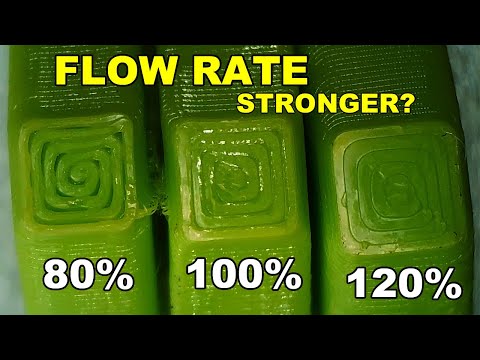

In this video I would like to see what is the effect of the extruding flow rate (or extrusion multiplier) to the strength of 3D printed object. The idea came when I did the review of digital microscope and I was analyzing a broken test specimen and I saw those gaps between the printing lines.

Material: 3D Active PLA, max walls (perimeters), 215°C/60°C (additional test with 2 perimeters and 20% infill). Printed on Prusa MK3S

Digital microscope:

On Banggood: https://www.banggood.com/custlink/mKmyBwrJcj

Review video: https://youtu.be/DionUg-NkbY

Check E-steps (from 15:05): https://youtu.be/dvHlawF66Nw?t=905

Download STL of test objects and results as image (for mobile users, so you can zoom in)

https://www.mytechfun.com/video/152

How can you support my work?

- Like the video if you liked it

- Just share this video on social network

- Patreon: https://www.patreon.com/mytechfun

- Buy me a coffee: https://www.buymeacoffee.com/mytechfun

- Paypal donation: https://www.mytechfun.com/donation

Contents:

0:00 About flow rate

0:44 Settings in Prusa Slicer

1:03 Settings in Cura

1:18 Introducing the experiment

1:50 About test specimens

3:59 Dimensions and weight

5:46 Under the microscope

6:18 Layer adhesion test

7:25 Tensile test

8:50 Hook test

10:09 Results

12:05 Additional test

13:20 Conclusions

#3dprinting

0 Comments